Application of ozone in drinking water

There are three main ways in which ozone can be applied in drinking water treatment:

1. Ozone, as a disinfectant for drinking water, is widely used in Europe. However, after ozone disinfection, a certain amount of residual chlorine needs to be added at the front of the pipeline to maintain the stability of the water quality in the pipeline system.

2. Ozone is added before the coagulation and sedimentation tank as a pre-treatment for water treatment. Its function is to remove iron oxide and manganese ions, remove color and odor, improve flocculation and filtration effects, replace chlorine addition, and effectively reduce the generation of halogenated hydrocarbon disinfection by-products.

3. In the deep treatment of drinking water, ozone is often combined with granular activated carbon to form the ozone biological activated carbon process. Through multiple processes such as ozone oxidation, activated carbon

adsorption, and microbial degradation, the effluent quality is effectively improved. In terms of sewage treatment, the combination of ozone and various technologies has been widely applied, such as ozone ultraviolet, ozone hydrogen peroxide, ozone catalytic oxidation, etc. In recent years, advanced ozone oxidation technology has been widely adopted as a deep treatment, decolorization, and disinfection process in a batch of newly built sewage

and reclaimed water plants in China.

SanKang ozone generator for drinking water treatment

The application of ozone in drinking water is currently mainly through the ozone biological activated carbon process, which is a deep treatment process for ozone in drinking water. The modified process uses the strong oxidization of ozone to remove dissolved organic matter and trihalomethane precursors in water, and the substances that produce odor include 2-MIB, unfashionable, musty smell, and fishy smell. It also kills bacteria and viruses in water and deeply purifies drinking water.

The use of ozone in water plants is becoming increasingly widespread. Ozone generators, as the name suggests, are devices that produce ozone gas (O3). Widely used in drinking water, sewage, industrial oxidation, food processing preservation, drug synthesis, space sterilization and other fields. The ozone gas generated by large ozone generators can be used directly or mixed with liquids to participate in the reaction.

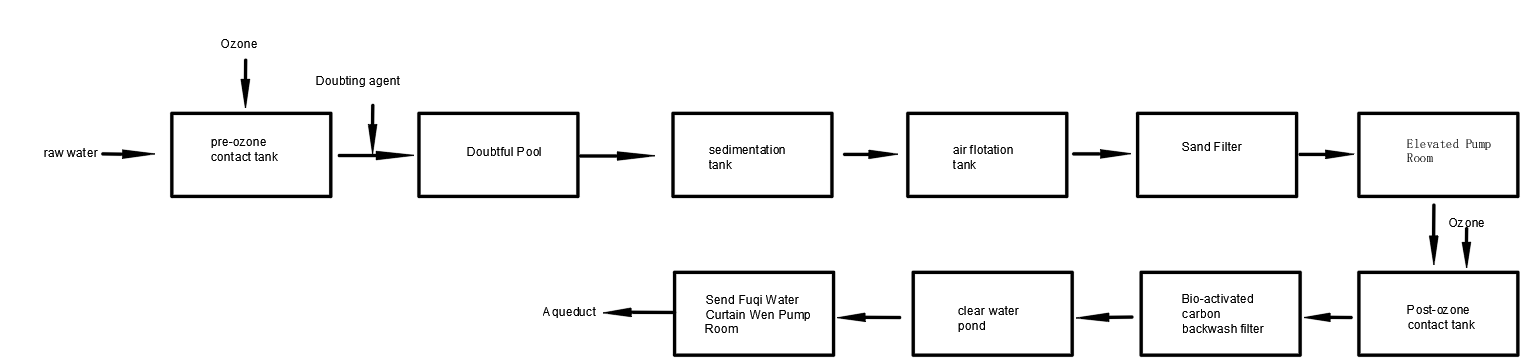

The water plant adopts O 3conventional treatment+O3-BAC process. As shown in the following diagram:

Ozone injection points are divided into two stages - pre ozone and post ozone. The contact time of the front ozone contact tank is 4 minutes, and it is added through a jet injector. The designed ozone dosage is 0.5mg/L-1.0mg/L, and the effective water depth is 6.0m. The rear ozone contact tank is divided into 2 compartments, with 3 injection points in each compartment, and the injection ratio is 6:2:2. The effective water depth is 6.0m, and the contact time is about 10 minutes. Micro porous ceramic discs are used for air distribution, and the designed ozone dosage is 1.5mg/L-2.5mg/L.

2. Overall control mode and requirements of the system

The overall control system can display the process flow and equipment operation status of the ozone system, achieve process parameter settings, etc. It can determine whether to alarm or automatically shut down at the same time when a fault occurs in the ozone system according to the nature of the fault pre-set. Alternatively, it can level alarms according to the nature of the fault, prompting the operator to input instructions based on the nature of the fault to determine the handling method.

Ozone generation control method: The amount of ozone generated is controlled according to the needs by "constant ozone concentration, adjusting oxygen flow rate and power dosage".

Pre ozone dosing control: Automatically adjust the dosing amount based on changes in the inlet flow rate and dosing ratio setting of the pre ozone contact tank.

Post ozone dosing control: Automatically adjust the dosing amount based on changes in the inlet flow rate and dosing ratio setting of the post ozone contact tank to ensure that the effluent reaches the set residual ozone value.