Ozone denitrification technology: principles, design and application analysis

1. Technical Overview and Background

DeNOx Technology Overview

Currently, there are several mature deNOx technologies on the market, including selective catalytic reduction (SCR), selective non-catalytic reduction (SNCR), and ozone deNOx. Each of these technologies has its own advantages and is suitable for different environments and conditions. For large coal-fired boilers, SCR is generally the preferred technology; for waste incineration, cement kilns, or circulating fluidized bed (CFB) boilers, SNCR is more economical and applicable. However, some units may not be fully suitable for either technology. In these cases, ozone oxidation deNOx becomes a suitable alternative.

This article will delve into the principles, chemical reactions, key influencing factors, system configuration, and CFD-assisted design of ozone deNOx.

Advantages of Ozone DeNOx

Due to the powerful oxidizing properties imparted by ozone's instability, ozone deNOx eliminates the need for catalysts and reducing agents, achieving zero emissions. This method is not only cost-effective but also demonstrates the advantages of requiring no absorbent, catalyst, or pollution in the FCC (catalytic cracking) process, making it an advanced solution for nitrogen oxide pollution control.

2.Principle and application of ozone denitrification

Ozone (O3) is a high-energy form of oxygen. It is colorless but has a distinctive odor and is extremely unstable. However, this instability gives it powerful oxidizing properties, enabling it to be highly effective in sterilization, decontamination, bleaching, and deodorization. In the water treatment sector, ozone is widely used to sterilize and disinfect drinking water, removing pollutants such as organic compounds through artificial ozone generators without causing secondary pollution.

Nitrogen oxide control

Ozone is an effective method for controlling nitrogen oxide pollution, particularly in the FCC process, where it has been widely used to remove nitrogen oxides. This method requires no catalysts or reducing agents and achieves a zero-emission, cyclical cleaning process.

Ozone reacts with nitrogen oxides

Ozone reacts rapidly with nitrogen oxides, requiring no catalyst and producing only oxygen and water. Its advantage lies in its high selectivity. By controlling the reaction time and amount of ozone, the oxidation reaction on compounds such as CO and SOx can be easily controlled, thereby increasing ozone utilization in the denitrification process.

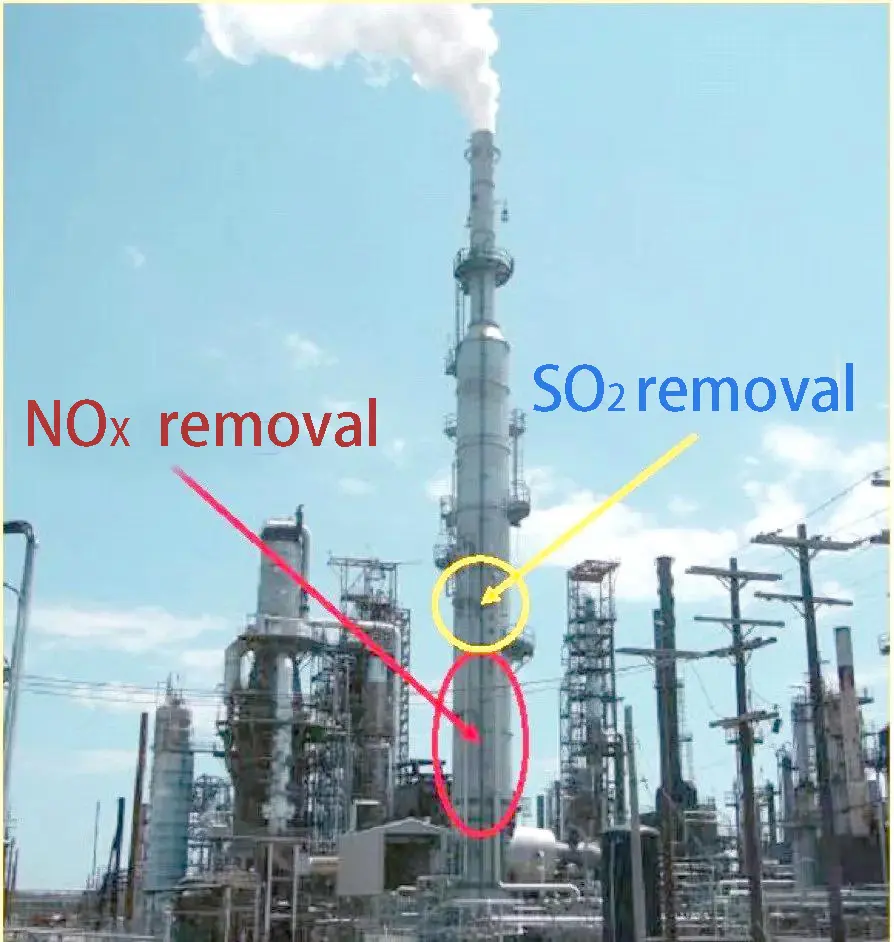

3.Composition of ozone denitrification system

The ozone denitrification system primarily consists of an ozone generator, a reactor, an absorbent, and a control system. The ozone generator produces ozone, the reactor facilitates the oxidation reaction between NO and ozone, and the absorbent further absorbs the resulting high-valent nitrogen oxides. The control system regulates various parameters throughout the denitrification process to ensure both effectiveness and safety.

System design and influencing factors

The effectiveness of ozone denitrification is affected by multiple factors, including molar ratio, concentration field, reaction temperature, reaction time, and the characteristics of the absorption liquid. These factors must be comprehensively considered in the design to achieve efficient denitrification and desulfurization.

The role of CFD simulation in design

The ozone oxidation process relies heavily on CFD simulation technology to optimize ozone grid design and flue gas temperature control. The simulation aims to ensure sufficient contact and collision between flue gas and ozone, thereby improving system efficiency and performance.

By gaining a deeper understanding of the principles and system design of ozone denitrification, combined with advanced simulation technology, we can achieve higher denitrification efficiency and lower operating costs in engineering practice, making greater contributions to environmental protection. At the same time, the accumulation of field application experience also provides valuable reference for further optimization of this technology.