Application of Sankang 40g/h ozone generator in swimming pool water disinfection

With the continuous development of society and the continuous improvement of people's material, spiritual and cultural levels, swimming pools and venues for various purposes have sprung up everywhere. In the field of swimming pool disinfection, ozone disinfection, as a safe and effective disinfection method, has been widely used in swimming pool water treatment systems.

Ozone has extremely strong oxidizing properties and high-efficiency spectral bactericidal properties. In terms of sterilization mechanism, the strong oxidizing property of ozone enables it to produce biochemical reactions with microorganisms such as bacteria, viruses, and pathogens at a certain concentration. Ozone generator penetrates into bacteria or viruses, causing RNA, lytic bacteria and other substances in the bacteria to be oxidized and decomposed, and the bacteria cannot survive, thus achieving a sterilization effect.

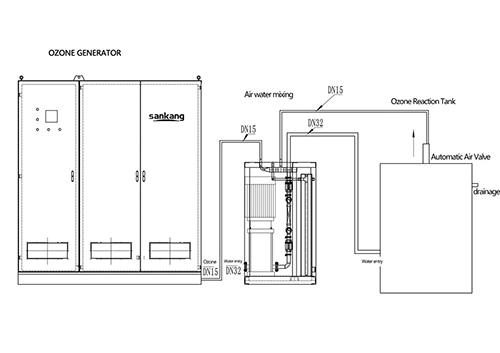

Ozone disinfection system design

1. Full-flow ozone disinfection system: the entire circulating flow is fully mixed with the added ozone for contact reaction. It not only ensures the disinfection effect, but also ensures the water quality of the pool. However, this method requires more equipment (in addition to the filter, there are also mixers, reaction tanks and residual ozone adsorption filters, etc.), with large investment and good effect. It is suitable for world-class, national-level and large swimming pools.

Its characteristics are: the entire circulating water volume of the swimming pool is sand filtered, and 0.8~1.0mg/l of ozone is injected into the reaction tank for contact reaction for no less than 2 minutes, and then enters the activated carbon to filter and adsorb the participating ozone and other impurities and odors, and then returns to the swimming pool.

2 Split-flow ozone disinfection system: only 25% of the circulating volume is added with ozone for disinfection, and then it is mixed with 75% of the mainstream circulating water without ozone, diluted and the remaining ozone in the split-flow disinfection water is used to continue disinfection. This disinfection method reduces the volume of the reaction tank and eliminates the residual ozone adsorption filter, thereby reducing the footprint, reducing investment, and reducing operating costs, while ensuring the disinfection and sterilization effect. This disinfection method does not require much additional equipment and is small in size, making it most suitable for the renovation of crude oil swimming pools and the use of small swimming pools.

Its characteristics are: ozone is usually introduced into the water by an ejector installed on the bypass pipe. In order to ensure the water inlet pressure of the ejector, a pipeline pump is installed on the bypass pipe to increase the pressure. The water and ozone mixed liquid after the ejector enter the reaction tank from the upper side and fully contact each other. The water is discharged from the small side and connected to the swimming pool circulating water main. The water in the bypass pipe is disinfected under high ozone concentration and then mixed with the water in the main pipe to produce oxygen reaction.

Sankang swimming pool ozone generator adopts negative pressure technology. The main working principle is: negative pressure (vacuum degree) is obtained by ejector or other methods to make air flow and enter the VPSA oxygen production system. VPSA oxygen production is designed according to the principle of low-pressure adsorption and vacuum desorption, that is, adsorption during pressurization and regeneration during vacuum adsorption. Then the characteristics of this technology are wide working pressure adaptation range, low gas dew point, high oxygen purity and easy operation.

The biggest advantages of negative pressure swimming pool ozone generator are: simple operation, reliable operation, reduced cost, negative pressure ozone generator reduces the investment in compressed air equipment, the air drying process is completely controlled by the established program, the working status is timely fed back, and gas leakage is effectively avoided, which improves the operation safety.